Plant Maintenance And Safety

Monitoring Key Fermentation Information in RealTime to Improve and Optimize the Quality and Production in Ethanol Plants;.

Plant maintenance and safety. Plant and equipment maintenance Maintenance on plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively Maintenance may. By Mandy Sunderland, Senior Industrial Hygienist It is recognized that wellplanned and executed outages are far less expensive and much safer than taking a reactive approach and responding to unplanned failures as they occur. Occupational Health & Safety is the industryleading news magazine, eNewsletter, and website for occupational health and safety professionals focusing on problemsolving solutions, latest news.

Becoming a Content Partner Speaking and Exhibiting at the Virtual Plant Maintenance & Safety Summit Platinum Level Sponsors Gold Level Sponsors Supporting Organizations Media Partner Produced By VIRTUAL EVENT — December 1617, Register Now Register Now. Plant, Maintenance & Safety () MCQ MCQs of Industrial Safety Next MCQ No 1 Without paying attention towards what will be its result, the acts of variable working gets implemented unknowingly, suddenly & hastily leading to the injuries to workers & to damage the properties is known as _____. The Plant Maintenance and Safety Summit is a oneandahalfday virtual event for biofuels industry professionals, including fieldbased presentations and networking opportunities With a focus on production efficiency, plant optimization, advanced maintenance, safety, and other areas of facility operations, this show provides a great opportunity to learn from industry experts who will offer the latest in new technology and maintenance solutions.

Aldon® Guardian® Trailer Stabilizers;. Truck Dock Safety Truck Dock Accessories;. Plant, Maintenance & Safety () MCQ MCQs of Industrial Safety Next MCQ No 1 Without paying attention towards what will be its result, the acts of variable working gets implemented unknowingly, suddenly & hastily leading to the injuries to workers & to damage the properties is known as _____.

Every person working in plant should wear safety accessories such as gloves, apron, helmet etc Handrails must be provided for stairs, ladders and top floor levels Electrical wiring should be inspected regularly Entry access into the manholes of cement or aggregate compartments must be limited. Plant Maintenance & Safety Summit DECEMBER 16–17, The Plant Maintenance and Safety Summit is a oneandahalfday virtual event for biofuels industry professionals, including fieldbased presentations and networking opportunities. Truck Dock Safety Truck Dock Accessories;.

331 General organization of safe maintenance Plant Management Team had the overall responsibility for the program A safety expectation letter was distributed to the key from each supervisor to their staff respective subordinates describing clearly the responsibilities and expectations for each person. UWA Plant and Equipment Safety Procedures 2 of 21 Definitions Further information see Appendix 6 Plant Plant is “any machinery, equipment (including scaffolding), appliance, implement or tool and any component or fitting thereof or accessory thereto” Plant is machinery that processes material by way of a mechanical action which. The period from the 1990s has seen a large body of work in the areas of Plant Maintenance and Reliability Management While strategies like RCM and TPM are popular and well known, there is also a.

Have a procedure that allows workers to report damaged or faulty equipment;. Dos and don’ts of plant and equipment maintenance Ensure moving plant has stopped and isolate electrical and other power supplies Most maintenance should be carried out with the power off If the work is near uninsulated, overhead electrical conductors, eg close to overhead travelling cranes, cut the power off first. Miscellaneous Maintenance & Repair;.

Difference between Irosion Corrosion and Pitting Corrosion. Abstract and Figures Safety in maintenance is concerned with the freedom from danger, protection from or not being exposed to the risk of harm or injury during the process of carrying out. In the continuing difficult economic times, plant reliability is essential to ensure strong oil and gas production levels and prevent unplanned maintenance work Plant reliability also has its part to play in ensuring minimal damage to the environment is caused as a result of oil and gas operations.

Plant, Maintenance & Safety () MCQ MCQs of Recovery, Reconditioning and Retrofitting Next MCQ No 1 The activity of repairing of worm out parts to recover its original shape, size, dimension & strength is called as _____ (A) Recovery. Blue Lights for Safety;. Operations, Maintenance, & Safety” – Practical Ways to Apply IEEE Std 3007 TM This intensive oneday training session covering operation, maintenance, and safety of plant electrical power systems, instructing engineers in practical ways to use Std 3007 The format will be to present a section from the Standard, offer insights into the.

Sign up now Guests and host Gene Hites is a Mining and Milling Maintenance Manager at The Doe Run, a Missouribased natural resources company He understands the need to implement a robust and reliable. When used to vaporize gas from the LNG plant Maintenance General (1) All components in service shall be maintained in sound condition consistent with operational or safety purposes The operato r shall keep and update written maintenance procedures for all components whose failure to fun ction as. Plant safety is critical to productivity Proper plant maintenance plays a significant role in reducing unscheduled downtime and improving safety Maintenance schedules for plant equipment exist for a reason Machinery and equipment that is not properly maintained can be very dangerous Even equipment with failsafes can malfunction if you do not perform regular maintenance checks.

Maintenance has long been considered a necessary evil in operating plant instrumentation With the right consideration however, maintenance, including verification, calibration and routine checks, can add real value through improved reliability, uptime and optimisation of plant applications Neil Ritchie and Mark Allinson of ABB stress that a good operations strategy can only work if the frontline instruments are properly applied and maintained. Mine Plant Maintenace Safety is discussed. Maintain plant and equipment regularly – use the manufacturer’s maintenance instructions as a guide, particularly if there are safetycritical features;.

162 topics in the Plant Engineering and Plant Maintenance PDF Handbook This best practise maintenance PDF book is useful on countless maintenance problems It has an extensive resource of engineering and maintenance solutions for solving industrial plant engineering and plant maintenance problems. Ask most plant managers about why manufacturing equipment maintenance is important, and you’re likely to hear about downtime and cost control Food safety, unfortunately, rarely comes up Yet along with sanitation, allergen control, food traceability and the like, equipment maintenance is a critical factor in safe food product production. As a maintenance group, many of our responsibilities are to maintain equipment in a fully functional state Repairing and maintaining equipment is only part of our duties Often, we are saddled with safety responsibilities like fabricating guards, building handrails, and other issues to keep.

Lifting and Towing Devices;. This Safety handbook is designed to provide key highlights of the Facilities Management safety requirements and procedures More complete information on each topic is readily available by accessing the specific EH&S policy cited in each section of this book Any questions or concerns about your safety should be discussed with your supervisor or. Freight Car/Locomotive Repair Railcar Stabilizing Jack;.

Plant Outage Safety Make a List and Check it Twice!. Plant, Maintenance & Safety () MCQ MCQs of Fundamentals of Maintenance Engineering Next MCQ No 1 To keep the machine plants & process equipment in there efficient condition, the maintenance activities are planned & carried out is known as _____ (A). Contributory factors for an assessor to consider concerning maintenance procedures The Safety Report should address the following points Whether the company maintenance regimes (planned,.

Repair Complexity And Its Uses. Plant safety is critical to productivity Proper plant maintenance plays a significant role in reducing unscheduled downtime and improving safety Maintenance schedules for plant equipment exist for a reason Machinery and equipment that is not properly maintained can be very dangerous Even equipment with failsafes can malfunction if you do not perform regular maintenance checks. 1000 am – 1030 am Virtual Networking Break Dedicated Expo Time 1030 am – 10 pm Plant Uptime;.

Plant, machinery and equipment Machine safety is everyone’s responsibility – including managers, supervisors, maintenance workers and employees Plant includes machinery, equipment, appliances, containers, implements and tools and components or anything fitted or connected to those things Some examples of plant include lifts, cranes, computers, machinery, scaffolding components, conveyors, forklifts, augers, vehicles, power tools and amusement devices. Proper plant maintenance plays a significant role in reducing unscheduled downtime and improving safety Maintenance schedules for plant equipment exist for a reason Machinery and equipment that is not properly maintained can be very dangerous Even equipment with failsafes can malfunction if you do not perform regular maintenance checks. Ask most plant managers about why manufacturing equipment maintenance is important, and you’re likely to hear about downtime and cost control Food safety, unfortunately, rarely comes up Yet along with sanitation, allergen control, food traceability and the like, equipment maintenance is a critical factor in safe food product production.

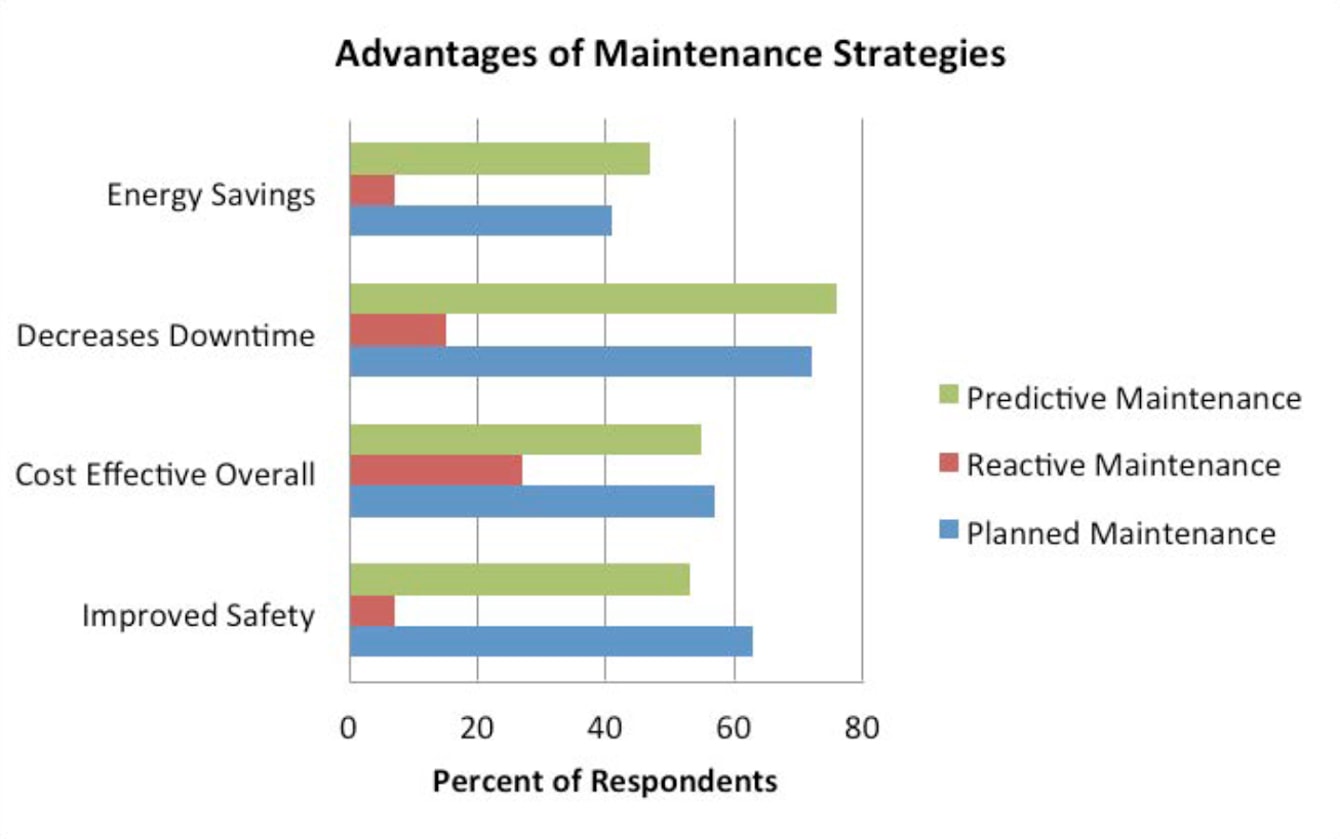

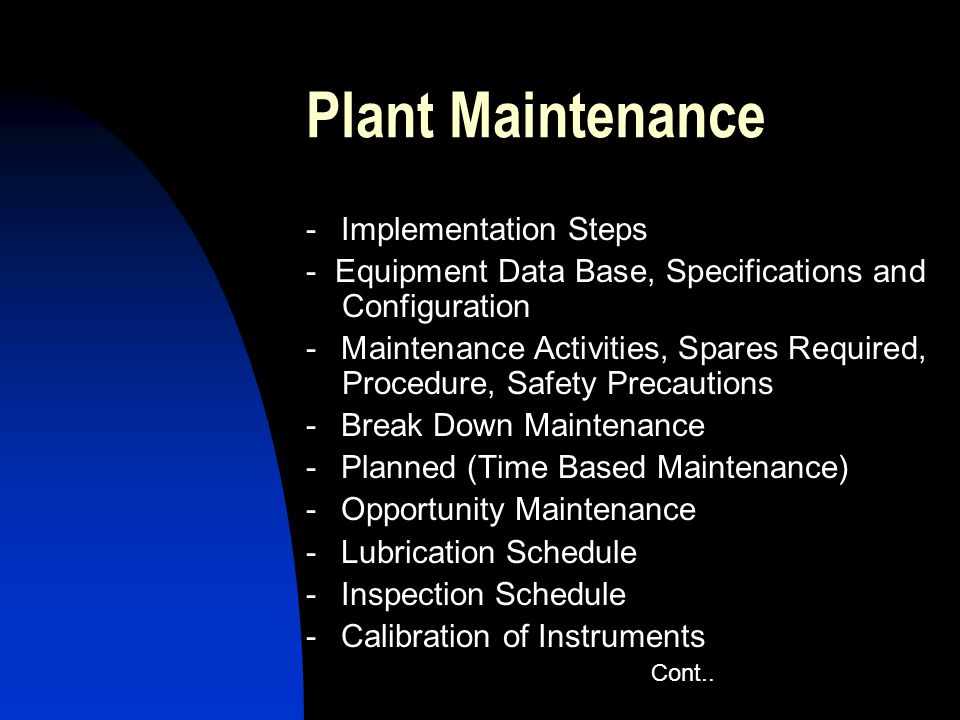

Maintenance management programs are highly customizable and centered around the type(s) of maintenance employed at a plant Whether you're using a conditionbased maintenance program like predictive maintenance or a more timebased maintenance program like preventive maintenance , it's important to focus your program on the type of maintenance. 8 Safety Tips Every Plant Should Follow Safety Equipment All workers should wear the required safety gear while on the premises The equipment must also be Risk Assessment To protect yourself and those around you, always be aware of what could go wrong and what you can do to Safety Training. Key Metrics and Ideas from a 99% uptime Ethanol Plant Maintenance Manager.

The steps needed to ensure plant safety;. By introducing the element of planning into your maintenance function, you are likely to reduce your repair and manpower requirements Exploratory maintenance to anticipate and prevent breakdowns Diagnostic measures to analyze your plant requirements include Operating and performing specifications of equipment Past experience with components. There are a few reasons a company might need to shut down all or a portion of its plant, such as preventative maintenance or equipment replacement, repurposing the facility (a turnaround) or closing the plant permanently No matter the reason, a shutdown or turnaround can be a dangerous proposition Often, th.

Maintenance, security, or fire protection of an LNG facility or plant within the jurisdiction of the Commonwealth of Massachusetts (4) 2 CMR 110 applies to each new facility or plant installed after the. There are a few reasons a company might need to shut down all or a portion of its plant, such as preventative maintenance or equipment replacement, repurposing the facility (a turnaround) or closing the plant permanently No matter the reason, a shutdown or turnaround can be a dangerous proposition Often, th. Looking for new ways to improve plant maintenance is always in the back of the mind of every maintenance manager The inspiration for this article, however, was the COVID19 pandemic that already stopped, or will soon stop, many production lines that are not deemed essential reviewing if all safety equipment is in place and working.

Effective maintenance programs can help plants avoid spurious trips and shutdowns Role of a safetyinstrumented system In process industry operations, the distributed control system (DCS) manages the normal operation of the plant, whereas the safetyinstrumented system (SIS) protects life, the environment, and the equipment being monitored. 162 topics in the Plant Engineering and Plant Maintenance PDF Handbook This best practise maintenance PDF book is useful on countless maintenance problems It has an extensive resource of engineering and maintenance solutions for solving industrial plant engineering and plant maintenance problems. By introducing the element of planning into your maintenance function, you are likely to reduce your repair and manpower requirements Exploratory maintenance to anticipate and prevent breakdowns Diagnostic measures to analyze your plant requirements include Operating and performing specifications of equipment Past experience with components.

Objectives of Plant Maintenance (i) The objective of plant maintenance is to achieve minimum breakdown and to keep the plant in good working condition at the lowest possible cost ADVERTISEMENTS (ii) Machines and other facilities should be kept in such a condition which permits them to be used at their optimum (profit making) capacity without any interruption or hindrance. Plant maintenance portal Safety Electrical safety surges ahead Factoring reliability into safety systems In addition, workers also need to know the neighborhood. Plant safety has to be addressed well before the plant is fully constructed All safety related points must be identified and proper care should be taken to address each point All employees should know the plan of action in case of emergency, and a safety document with clearly identified steps needs to be part of employees' vocabulary.

Plant Maintenance Resume Samples and examples of curated bullet points for your resume to help you get an interview Fire Safety Equipment Inspection 5 – 7 years experience in plant maintenance or related activity BES Certificate, preferably level 1 or 2 or related engineering equivalent. Freight Car/Locomotive Repair Railcar Stabilizing Jack;. Anything that moves in a plant experiences wear and tear and needs upkeep One critical but often overlooked task is keeping maintenance and safety logs, which will help in identifying equipment failures Keeping pumps operating successfully for long periods requires careful pump design selection.

Plant Outage Safety Make a List and Check it Twice!. Ensure maintenance is carried out by a competent person (someone who has the necessary skills, knowledge, and experience to do the work safely);. Plant Maintenance Portal Safety Plant Services' safety portal helps you stay uptodate with plant industry safety Aug 07, 09 PlantServicescom has assembled a list of safetyrelated articles and put them in one place Make sure you keep this page bookmarked and come back often — we're always updating!.

Regular maintenance is essential to keep equipment, machines and the work environment safe and reliable Lack of maintenance or inadequate maintenance can lead to dangerous situations, accidents and health problems Maintenance is a highrisk activity with some of the hazards resulting from the nature of the work. Miscellaneous Maintenance & Repair;. December 16, 11 admin typically goes into planning and coordinating the various aspects of a major outage to maximize repairs and preventive maintenance that can only be conducted in “shut down” mode It is critical that all issues, like industrial hygiene, rescue and safety.

Blue Lights for Safety;. Several technical safety improvements were implemented so far during the plant wide maintenance risk assessment activities The lessons learned gained during this initiative were included in machinery specifications for upcoming new projects Ford Otosan leadership promotes health and safety improvements Maintenance employees are. How lubrication can help reduce humanmachine interaction (HMI) How safety impacts the bottom line;.

Aldon® Guardian® Trailer Stabilizers;. Lifting and Towing Devices;.

Plant Maintenance And Safety Bearing Mechanical Machines

Plant Maintenance And Safety Bearing Mechanical Machines

Urgent Safety Assessment Over Maintenance Job Cuts At Fife Ngl Plant Royal Dutch Shell Plc Com

Plant Maintenance And Safety のギャラリー

How Predictive Maintenance Enhances Plant Safety Without Sacrificing Productivity Ue Systems

Pdf Business Model Of Plant Maintenance For Lifecycle Safety Semantic Scholar

Safety Boiler Inspection And Maintenance Plant Services

Virtual Event Plant Maintenance Safety Summit Waste Advantage Magazine

Plant Maintenance And Safety Instsignpost S Blog

Maintenance Systems For The Dairy Plant

Download Plant Safety And Maintenance Pdf Online By Dhone

Plant Maintenance And Safety Summit

Importance Of Power Plant Maintenance For Smooth Functioning Of Machines By Equipment Maintenance And Repair Issuu

Q Tbn And9gcrn6rucuvcoz5wscmpsqhzwlhi X9ponyb26stkl4fnpbbxn U8 Usqp Cau

Pdf Business Model Of Plant Maintenance For Lifecycle Safety Semantic Scholar

Break Down Of Safety Equipment Of An Nuclear Power Plant Source Download Scientific Diagram

Engineering Maintenance Improving Plant Safety Volume 2 Chemical Engineering Store

Preventive Plant Maintenance Resources Isa

Maintenance Of Pump In Oil Gas Processing Plant Editorial Image Image Of Pumping Delay

Design Of Plant Safety Model In Plant Enterprise Engineering Environment Sciencedirect

Q Tbn And9gcrs0kduv5rotzap0co4fnebsrswzx6grgszsbdwcnapdqhn1wab Usqp Cau

Plant Maintenance Manager Resume Sample Mintresume

Best Practices In Plant Maintenance And Safety Improve Operational Efficiency 16 12 21 Food Engineering

Plant Engineering Maintenance Study Mobil

Annual Maintenance Budget Estimation For A Plant System Digraph Model And Matrix Approach Emerald Insight

Lean Sustainability Creating Safe Enduring And Profitable Operation

Osha Europa Eu En Publications Risk Assessment Maintenance Hazards And Identification Safe Maintenance Methods

Helping Sap Make Sense Of Condition Based Maintenance Workflows Efficient Plant

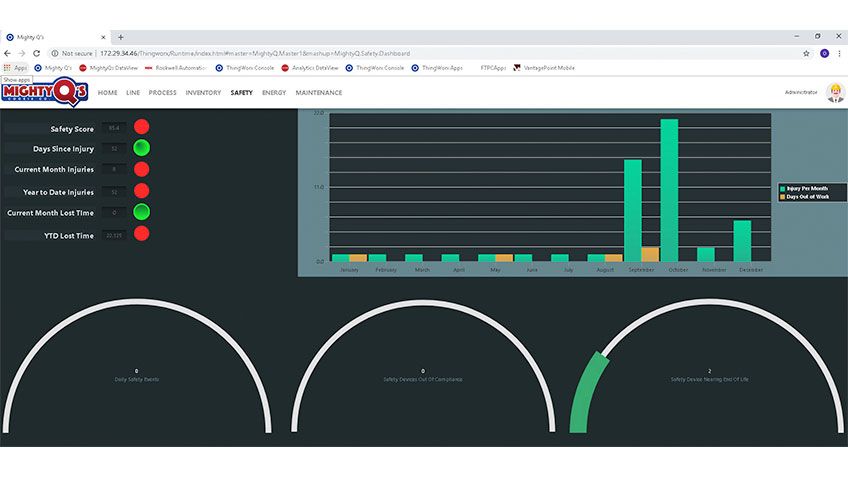

The Value Of Plant Safety Dashboards Rockwell Automation

Download Plant Safety And Maintenance Pdf Online By Dhone

Plant Engineering Top 5 Plant Engineering Articles October 26 Building Safety Into Maintenance Preventive Maintenance Welding Helmets More

Safety Guidance Safe Plant Plant Assessor

Food Plant Sanitation Design Maintenance And Good Manufacturing Pra

Safety Valve Maintenance In Power Plant Www Wtindustrialeqpt Com Safety Valve Power Plant Valve

Instill A Safety First Culture Among Your Maintenance And Repair Techs Global Electronic Services

Plant Maintenance Safety Summit Interstates

Plant Maintenance And Safety Pulp And Paper Canada

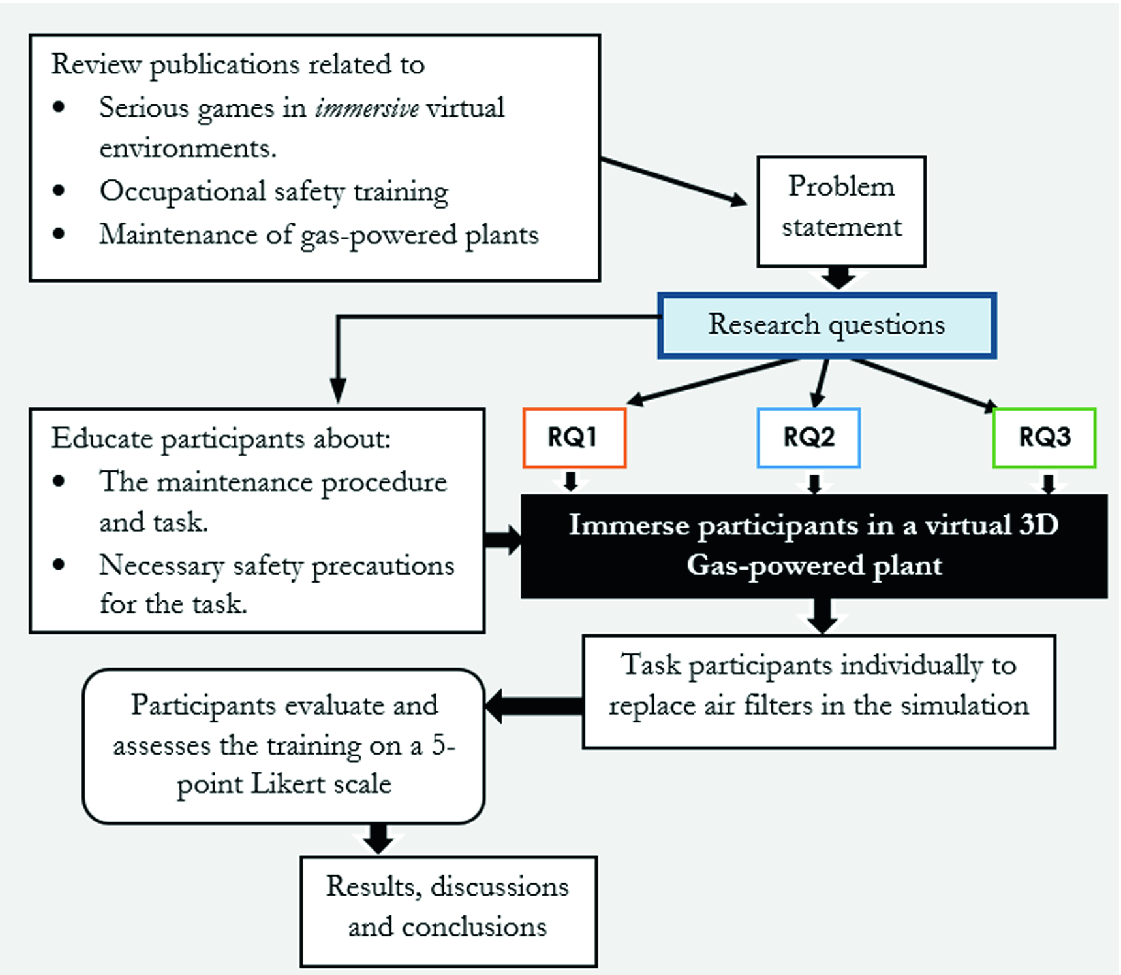

Simulation Based Safety Training For Plant Maintenance In Virtual Reality Springerlink

Plant Safety And Maintenance

About The Summit Plant Maintenance And Safety Summit

Why Should You Wear A Safety Helmet

O M Services Epc Business Jgc Holdings Corporation

Hazardex 12 Paperless Safety Lifecycle At The R Stahl Plant Engineering Center

Shoichi Yamamoto Plant Maintenance Office Manager At Japan Atomic News Photo Getty Images

We Are Providing Lot Of Maintenance Procedure For Your Safety There Are Various Types Of These Procedur Facilities Maintenance Maintenance Safety Procedures

Plant Maintenance Safety Youtube

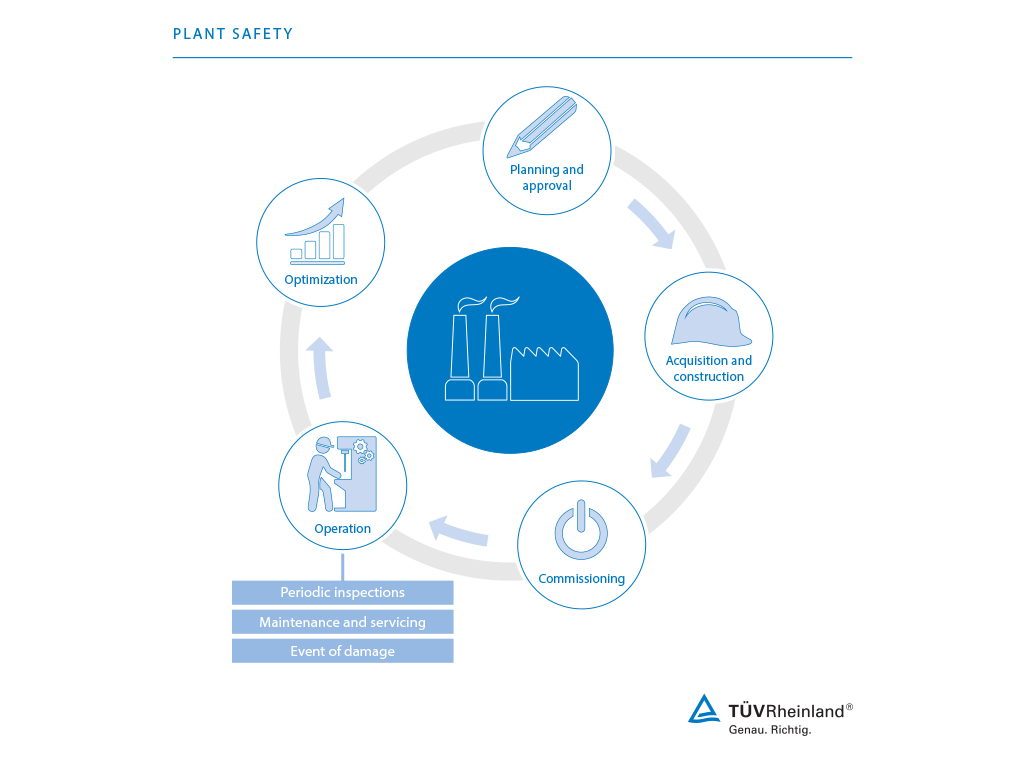

Plant Safety Cn Tuv Rheinland

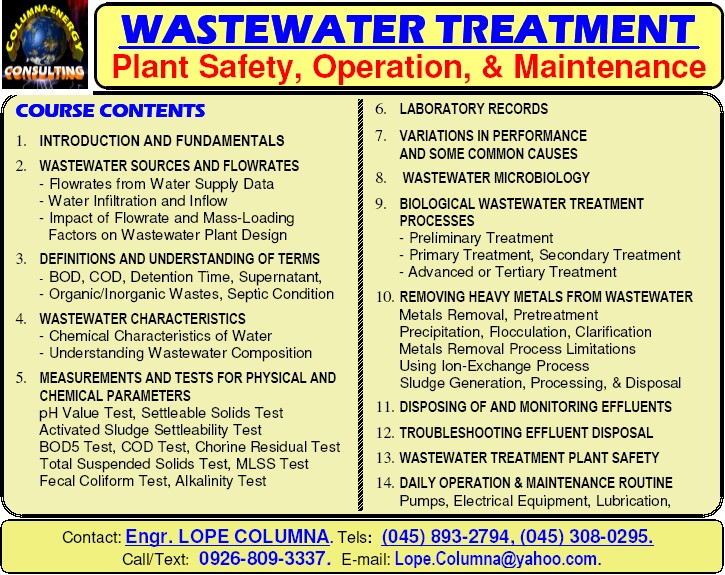

Columna Energy Wastewater Treatment Plant Operation Safety And Maintenance Course

Deepak Prakashan Publisher Of Technical Books Awarded By Aicte Govt Of India

Pdf Augmented Reality Applications For Nuclear Power Plant Maintenance Work

Plant Maintenance Hsse World

How Predictive Maintenance Enhances Plant Safety Without Sacrificing Productivity Asset Management Maintworld

Becoming A Content Partner Speaking And Exhibiting At The Virtual Plant Maintenance Safety Summit On Vimeo

Plant Engineering Effective Electrical Safety Starts With Maintenance

Mining Process Plant Maintenance Safety Training Resource Center

Entity Relationship Model For The Construction Plant Rdbms Health And Download Scientific Diagram

Power Plant Maintenance

Igus Smart Plastics To Increase Plant Safety And Reduce Maintenance Costs Asia Pacific Food Industry

Plant Maintenance And Safety Summit

Plant Maintenance A Practical Perspective Maintenance And Engineering

Plant Maintenance And Safety Youtube

Plant Maintenance And Safety Youtube

Plant Maintenance Safety Hindi Book Buy Online Bukwit Com

Ppt Plant Maintenance And Safety Powerpoint Presentation Free Download Id

What Is Plant Maintenance With Pictures

Maintenance Safety And Human Error In Aviation And Power Plant Maintenance Taylor Francis Group

Skills For Successful Management Of Plant Turnaround Maintenance Download Table

Safety And Maintenance Tips To Set Up In Your Plant Cjplantmaintenance

Maintenance Safety Work

Plant Maintenance Safety In English

Sap Plant Maintenance Notes Docx

Maintenance And Safety Planning 1 Personal Protective Equipment Fire Safety

Phase 6 Operation Maintenance Bioenergyfarm 2

A Reliable Plant Is A Safe Plant Hosny

Sil Manual For Plant Maintenance Engineering Iec Iec Manualzz

Total Productive Maintenance Ppt Video Online Download

Maintenance And Safety Plant Engineering

About The Summit Plant Maintenance And Safety Summit

6 Welding Tips For Plant Maintenance

Maintenance Safety A Proactive Approach For Industrial Professionals

Plant Maintenance And Safety Summit

Q Tbn And9gcszsql2gzjdejoz S5quvgme3nfvvavmlwzeq8ybv1ovuiay7qx Usqp Cau

How Predictive Maintenance Enhances Plant Safety Without Sacrificing Productivity Asset Management Maintworld

Cafm Maintenance Energy Asset Management Software Support Compass Afm

How Total Productive Maintenance Tpm Ensures Product Quality

Increase Plant Safety Reduce Maintenance Costs With Smart Plastics From Igus

What Is Plant Maintenance With Pictures

Control Engineering Knowing The Future Predictive Maintenance And Risk Mitigation

The Importance Of Industrial Plant Maintenance

Industry Standard Solution For Plant Maintenance Ispm

Maintenance And Changes In Plants With High Safety Requirements Safety Work

Plant Mechanic Resume Sample Mintresume

Technical Handbook Hydraulic Maintenance And Safety Construction And Industrial Plant Manuals

Amazon In Buy Plant Safety And Maintenance Book Online At Low Prices In India Plant Safety And Maintenance Reviews Ratings

Plant Maintenance And Safety Dp Semester 4 Mechanical English Medium Atul Ajay Book Stall

Safety Guidance Safe Plant Plant Assessor

Pdf Business Model Of Plant Maintenance For Lifecycle Safety Semantic Scholar

Plant Diagnosis Plant Maintenance Visual Inspection Ndi Techno Staff

Doc Enhancing Profitability Through Plant Maintenance Strategy Hisham Jabar Academia Edu

Human Factors And Human Error In Nuclear Power Plant Maintenance Taylor Francis Group

Re Inventing The Maintenance Process

Hazardex Risk Assessment For Plant Maintenance In The Digital Age

Mindsets That Lead To Unsafe Plant Maintenance And How To Change Them Manufacturing Net

Harsh Plant Maintenance And Safety Type Of Corrosion