Aluminium Casting

Aluminum casting is a type of metalworking process that involves pouring liquid metal into a mold or form Aluminum casting is a variation of this that uses only aluminum and aluminum alloys as the liquid metal that is poured into the mold Aluminum castings are used to make complex and detailed parts very efficiently.

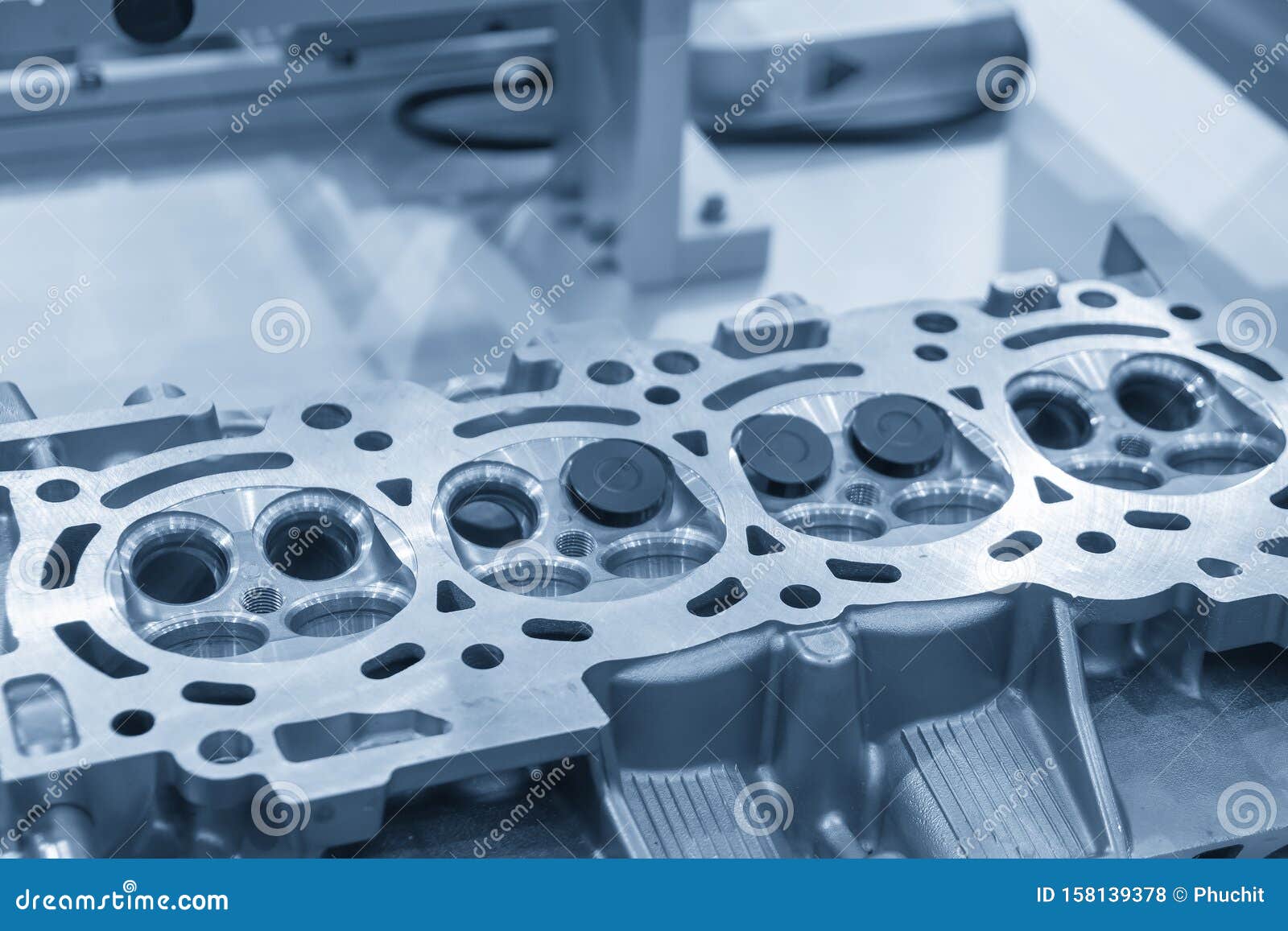

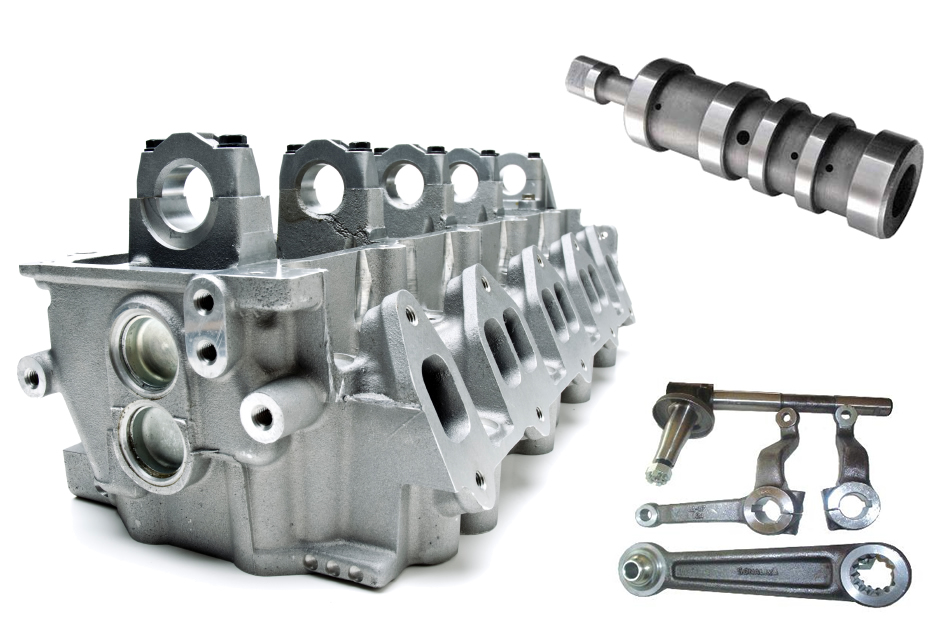

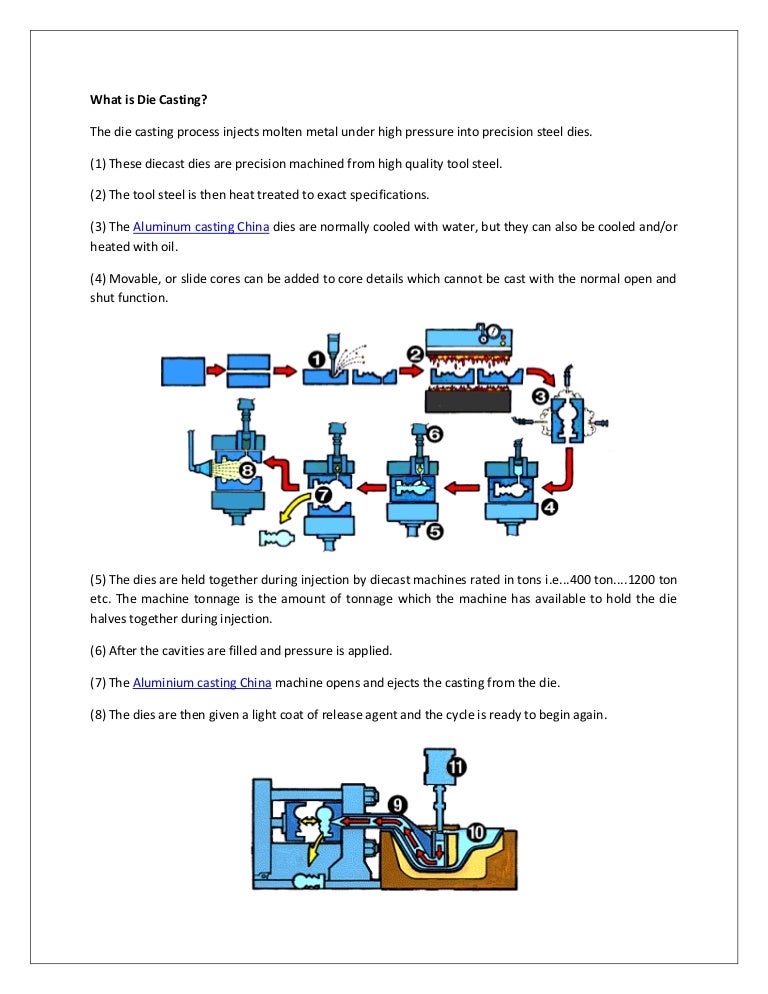

Aluminium casting. US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications. Casting is the original and most widely used method of forming aluminum into products Technical advances have been made, but the principle remains the same Molten aluminum is poured into a mold to duplicate a desired pattern The three most important methods are die casting, permanent mold casting and sand casting. The Aluminum Die Casting process retains a durable strength at very high temperatures, requiring the use of cold chamber machines The molten metal is still contained in an open holding pot which is placed into a furnace, where it is melted to the necessary temperature.

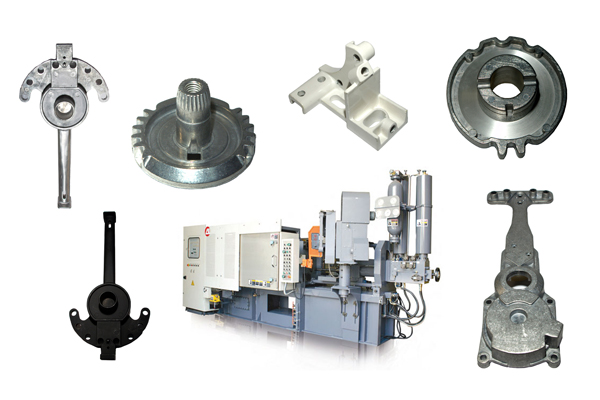

Aluminum casting is the process of creating aluminum shapes with a die caster Die casting is a very commonly used metal shaping process that is used to create metal shapes for use in industrial, commercial and consumer products contexts. Aluminum casting is a process that includes dispensing hot liquid metal into a particular form or mold The ingredient used in creating the hot liquid is aluminum or aluminum alloys This process is mostly used to metal products with detailed or complex components. Aluminum is one of the few metals that can be cast by all of the processes used in casting metals These processes, in decreasing order of amount of aluminum casting, are die casting, permanent mold casting, sand casting (green sand and dry sand), plaster casting, investment casting, and continuous casting.

Aluminum die casting is considered as a non expendable technique which can be repeatedly used to produce different shapes, sizes and thickness of die cast aluminum The die casting process can produce variety of shapes with accuracy and attractiveness Aluminum die casting is now considered as an industrial procedure for the purpose of creating aluminum for sale or made as part of machines or any other commercial or industrial production. HighQuality Aluminum Casting Eagle Aluminum Cast Products specializes in casting aluminum alloys through the greensand casting process We have decades of experience in pattern making, casting and finishing–all provided within excellent lead times Eagle Aluminum also maintains certification to ISO standards Using the traditional method of hand ladles and gravity to feed aluminum into molds, we provide quality castings with excellent lead times. Your single source manufacturer for permanent mold aluminum castings A one stop shop for tooling, casting, machining, powder coat & assembly.

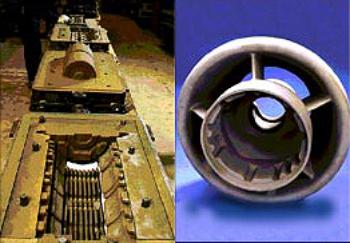

For metal castings with internal geometry cores are used A core is a replica, (actually an inverse), of the internal features of the part to be cast Like a pattern, the size of the core is designed to accommodate for shrinkage during the metal casting operation Unlike a pattern, a core remains in the mold while the metal is being poured. Jan 12, 21 (Heraldkeepers) Market Forecast The Global Aluminum DieCasting Machine Market is expected to exhibit a CAGR of 6% during the forecast period. Aluminium castings have many benefits when compared to the likes of steel or grey iron castings It produces strong, corrosionresistant castings with high electrical and thermal conductivity Aluminium castings are comparatively lightweight, which results in lower storage and transportation costs They are easy to machine and easy to recycle.

The most popular alloy for aluminum die casting is A380 We use A380 because it has demonstrably the best combination of physical and mechanical properties for casting, including being lightweight, very strong at high temperatures and corrosion resistant. Our aluminum sand casting operation begins with exceptionally high quality sand molds in the green sand and air set or no bake processes Our sand molding department consists of DISA automated molding, Rotolift, squeezer, Hunter , Hunter 32, a Kloster air set molding machine, and other air set lines The aluminum castings can also be highly cored using the shell sand, cold box, and oil sand core processes Producing our sand cores inhouse assures that everything going into our aluminum. Aluminium Casting We are one of the biggest Aluminium Casting China manufacturers, will offer you the 100% quality guarantee Die Casting service in aluminium, magnesium and zamak ( like zamak 3 or zamak 5 etc) We have years experiences in aluminium die casting service to the world with expert team (tool maker, mold design, project management, engineering) to support your business in die casting requirement.

There is very little functional. Aluminium Sand Casting ₹ 210/ Kilogram Get Latest Price Being on top position and widely known for casting business our company is providing the superb Aluminium Sand Casting Sturdiness and chemical resistance nature of our product has made it one of the highest selling of all times. There are aluminum alloys tailored for permanentmold casting including 319, 356, A356, 413, and 535 In general, silicon (Si) is the most important alloying element for any aluminum casting.

In handheld devices, aluminum castings provide EMI/RFI shielding, rigidity, and durability with minimal weight;. We began as pattern makers and today offer complete design assistance for wood and metal patterns, including close tolerance aluminum castings Our specialized knowledge enables us to meet customer needs for aluminum sand castings requiring up to seven cores. Aluminum Die Casting is A manufacturing process that produces accurately, defined, smooth and texturedsurfaced metal parts Accomplished by forcing molten metals into a mold form due to highpressure systems Corrosion resistant Highly conductive Have a good stiffness and strengthtoweight ratio.

Most die castings are made from nonferrous metals, specifically zinc, copper, and aluminiumbased alloys, but ferrous metal die castings are possible The die casting method is especially suited for applications where many small to mediumsized parts are needed with good detail, a fine surface quality and dimensional consistency. Jan 12, 21 (Heraldkeepers) Market Forecast The Global Aluminum DieCasting Machine Market is expected to exhibit a CAGR of 6% during the forecast period. Aluminum Castings Aluminum is a lightweight material known for its corrosion resistance and ease of machining When strengthened through additional alloying and heat treat conditioning, aluminum becomes a material that provides strength similar to mild, low carbon alloy steel, making it ideal for a range of aluminum casting applications.

Aluminum investment casting is a versatile solution used by a range of industries including military, aerospace, medical, automotive, heavy truck, agricultural, firearms and others It can be used for numerous parts and components including valves, medical devices, levers, appliances, hand tools, brackets, automotive parts, aircraft components, and machinery. Further attempts to get that ultrarealistic facial scaringForget building a forge, foundry, flux capacitor, all you really need to melt aluminum is a pro. Carve or sculpt the wax into the shape you want to cast in aluminum The process used for casting aluminum with plaster molds is called lost wax casting In this process, a model of the desired object is made of wax and coated in plaster After the plaster has dried, the wax is melted out of the mold and replaced with aluminum.

028LBS(128KGS) Gas/ Propane Metal Melting Furnace Kit, Stainless Steel 304, Up to 2600°F/1425°C,CRUCIBLE,TONGS Kiln,Melt Gold,Silver,Copper, Aluminum, Metal Casting Furnace,Jewelry Casting Tool 47 out of 5 stars 27. The most common aluminum casting alloys are the heattreatable 3XX0 series, such as 3560, 3570, and 3190 These are aluminumsiliconmagnesium (AlSiMg) alloys, but some, 3190, for example, also contain copper (Cu) The good news is that these alloys are all readily weldable with 4043 serving as the correct filler. Because of aluminum’s excellent electrical performance and shielding properties, even in hightemperature environments, die cast aluminum is ideal for electronic connectors and housings;.

Amazing Cast Aluminum Process Using Sand Mold, Fast Melting Metal Casting Technology Working. Recycling Aluminum Die Castings Did you know that over 95 percent of aluminum castings made in North America are made of postconsumer recycled aluminum?. Aluminum is an ideal material for a variety of castings processes, including investment casting, die casting, sand casting and permanent mold casting It is a material wellknown for its high strengthtoweight ratio, which makes it an ideal material for countless casting applications.

Cast aluminum is a specific metal that has gone through one of the several processes known as casting Essentially, it is created when methods such as die casting, mold casting, or sand casting are used to temper the aluminum for use in creating components for many different types of products. You can melt down almost any kind of aluminum—cans, even—but a piece that has already been cast (such as a water pump, wheel, or intake manifold) will have an alloy that's better suited for. Aluminum Die Casting Diecast aluminum is the kind of aluminum in which metals are molted in mold cavities under high pressure In aluminum die casting, molten metals are injected to metal dies, then cooled in the die cavities, and turned into a solidified form The molten metals sit in the cavities for longer for the purpose of cooling.

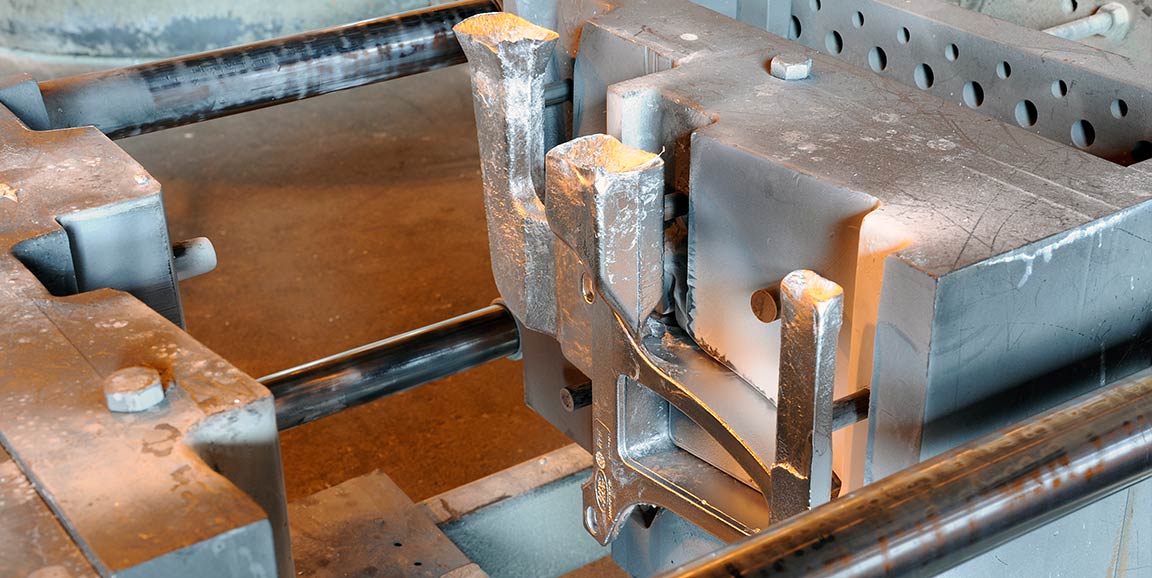

The oldest types of molds for aluminum casting are the molds that have been used since the time of the Egyptians These types of molds are made when a cavity is created in sand that is held in a box or "flask" Usually the original "pattern" is made out of wood, metal or other solid material. Metal casting is a modern process with ancient roots In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold Metal casting is arguably the earliest and most influential industrial process in history It’s used to make many of the metal objects. Let it heat the furnace for about 15 minutes Cover the top of the furnace with a brick Slowly feed the metal in until it reaches the level of the pipe fitting Pour the molten metal into the pan Let it cool for about 1/2 an hour, because the metal holds heat very well And now you have a dollop of solid aluminium!.

143 Japan Aluminium Casting Products Market Size and Growth Rate of Aerospace and Marine from 14 to 26 144 Japan Aluminium Casting Products Market Size and Growth Rate of Building and Construction Hardware from 14 to 26 145 Japan Aluminium Casting Products Market Size and Growth Rate of Power and Hand Tools from 14 to 26. There are aluminum alloys tailored for permanentmold casting including 319, 356, A356, 413, and 535 In general, silicon (Si) is the most important alloying element for any aluminum casting. Backyard Metal Casting and Homemade Forges For thousands of years, man has worked metals Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us.

143 Japan Aluminium Casting Products Market Size and Growth Rate of Aerospace and Marine from 14 to 26 144 Japan Aluminium Casting Products Market Size and Growth Rate of Building and Construction Hardware from 14 to 26 145 Japan Aluminium Casting Products Market Size and Growth Rate of Power and Hand Tools from 14 to 26. Types of Molds for Aluminum Casting Permanent Mold Casting Permanent types of aluminum casting molds are made from metals such as steel and iron The Die Casting Molds Die casting molds use steel dies or molds to produce a lot of identical castings With aluminum, as Shell Mold A shell mold. To recap, here are the pros and cons of cast aluminum vs cast iron Cast aluminum lightweight, heats up faster, does not hold heat as well, has a shorter longevity, is typically cheaper Cast iron heavier, heats up a little slower, holds heat better, lasts longer, is typically more expensive but easy to find.

Aluminum can be cast into nearly any shape resulting in castings of sculptures, art pieces or even tools Although casting aluminum involves very high heat and molten metal, it can be done at home with relatively little equipment Many people around the world cast aluminum, and many useful items have been produced by home casting. Aluminum Sand Casting Costs Jerry buys the aluminum sand casting for $21 each part and puts about $11 of machining into each aluminum casting part That is a total cost of $32 for his sand cast aluminum part Tooling for Jerry's aluminum sand casting costs him $1,500 for the pattern and the tool life, which Jerry said is 5,000 parts. Jan 12, 21 (Heraldkeepers) Market Forecast The Global Aluminum DieCasting Machine Market is expected to exhibit a CAGR of 6% during the forecast period.

Aluminum Casting Processes Die Casting Alloys of aluminum are used in die casting more extensively than alloys of any other base metal In the Permanent mold casting Permanent mold (gravity die) casting, like die casting, is suited to highvolume production Sand casting Sand casting, which in. Custom Aluminum Sand Casting We specialize in custom aluminum sand casting because unlike permanent mold and die casting, it’s the most versatile method available for casting aluminum parts and products We’ve offered this method for over 75 years with operations that include core making (utilizing industryleading Redford machines), green sand casting (utilizing Hunter Automatic Molding Machines) as well as air set molding — also known as nobake molding. ALUMINUM CASTING Stateoftheart equipment & technology puts us at a distinct competitive advantage over our competitors in the global casting market If you are a human and are seeing this field, please leave it blank Fields marked with an *are required.

Aluminum castings are formed by pouring molten metal into molds that have been shaped by a pattern of the desired final product Three common types of molding methods are used to produce castings die casting, permanent mold casting, and sand casting. US Aluminum Castings is a precision aluminum casting supplier located in Central Washington State As a full service foundry, we offer multiple casting processes as well as inhouse heat treat, machining, powder coating, and NDT Our castings are used in defense, aerospace, heavy truck, marine, and commercial applications. Ross Aluminum Castings is an Ohio based, US owned, stateoftheart aluminum foundry which has been producing aerospace castings, performance racing castings, diesel engine castings and power generation castings for almost eighty years Ross Aluminum Castings is one of the few aluminum casting suppliers that brings years of practical knowhow and problemsolving to the challenges of today's transportation, trucking, power generation, aerospace, manufacturing and specialty automotive industries.

143 Japan Aluminium Casting Products Market Size and Growth Rate of Aerospace and Marine from 14 to 26 144 Japan Aluminium Casting Products Market Size and Growth Rate of Building and Construction Hardware from 14 to 26 145 Japan Aluminium Casting Products Market Size and Growth Rate of Power and Hand Tools from 14 to 26. Jan 12, 21 (Heraldkeepers) Market Forecast The Global Aluminum DieCasting Machine Market is expected to exhibit a CAGR of 6% during the forecast period. Produces custom aluminum castings ranging from five pounds to 1 pounds, in flask sizes up to 48” x 60” Alloys poured include 319 – 356 – A356 – 535, per Aluminum Association Standards Heat treatments, performed inhouse, include T5, T51, T6, T61 and T7.

Metal Casting Processes There are numerous metal casting processes implemented in the manufacturing of parts Two main divisions can be identified by the fundamental nature of a mold they use There is expendable casting and longlasting mold casting Expendable molds are utilized for a single metal casting while longlasting molds are. There are many types of molds for aluminum casting that are used in casting molten aluminum into different shapes and forms Some molds are temporary, and others are permanent and can be used repeatedly These same types of molds are also used for many different metals and alloys besides aluminum. Aluminum casting is a process that includes dispensing hot liquid metal into a particular form or mold The ingredient used in creating the hot liquid is aluminum or aluminum alloys This process is mostly used to metal products with detailed or complex components.

Aluminum casting is also a widely used method, due in large part to the superior versatility of the metal As one of only a few materials able to undergo most metal casting processes, aluminum is a relatively adaptable substance to work with. 143 Japan Aluminium Casting Products Market Size and Growth Rate of Aerospace and Marine from 14 to 26 144 Japan Aluminium Casting Products Market Size and Growth Rate of Building and Construction Hardware from 14 to 26 145 Japan Aluminium Casting Products Market Size and Growth Rate of Power and Hand Tools from 14 to 26. Backyard Metal Casting and Homemade Forges For thousands of years, man has worked metals Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us.

Global Aluminum Casting Market By Type (Die Casting, Permanent Molding Casting, and Sand Casting), By Application (Automotive, Aerospace & Military, Engineering Machinery, and General Industrial Machinery), By Region and Key Companies Industry Segment Outlook, Market Assessment, Competition Scenario, Trends and Forecast 19–28 The report on Aluminum Casting Market offers indepth analysis on market trends, drivers, restraints, opportunities etc Along with qualitative information. 143 Japan Aluminium Casting Products Market Size and Growth Rate of Aerospace and Marine from 14 to 26 144 Japan Aluminium Casting Products Market Size and Growth Rate of Building and Construction Hardware from 14 to 26 145 Japan Aluminium Casting Products Market Size and Growth Rate of Power and Hand Tools from 14 to 26. Aluminium casting processes are classified as Ingot casting or Mould casting During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi and finished products.

Stencil Aluminium Casting Process By Julien Carretero

福联技术交流园地 Www Gdfulian Com

Q Tbn And9gcsr84yo7zuvocyiz Egqlhlp 21fcesrgu5jkwn1igqxxi5tphq Usqp Cau

Aluminium Casting のギャラリー

Die Casting Heater Aluminium Cast In Heater Leveranciers China Factory Prijs Hongtai Alloy

Aluminium Casting Heater Manufacturer Aluminium Casting Heater Supplier Exporter

Launder System Aluminium Casting Adtech China

Machined Castings Aluminium Casting Manufacturer From Mumbai

Aluminium Casting Turbocharger Compressor Housing

Aluminium Casting Scrap At Rs 100 Kilogram Sangrur Id

Simulation Casting Perla Alucast

Aluminium Casting Technische Voorbereiding Youtube

The Multi Axis Cmm Probe Measure Dimension Of The Aluminium Stock Photo Picture And Royalty Free Image Image

Aluminium Casting A Relief Wall Kikukawa

Composition And Temperature Of The Flue Gases In Aluminium Casting Download Scientific Diagram

G W P Ag Aluminum Sand Casting For Prototypes Sand Casting Foundry Aluminium Prototypes

Vee J Pee Aluminium Foundry Linkedin

Brass Metal Forging Manufacturing Foundry Brass Metal Aluminium Casting Png Klipartz

Distinctive Characteristics Of Aluminium Die Casting Process Came Spa

Rusal Inks Agreement With Sms Group To Develop Continuous Aluminium Casting Equipment Aluminium Insider

Aluminum Casting Jg Automotive Automotive Components Supplier

Suppliers And Exporters Of Aluminium Casting Alloy Trade

The Aluminium Casting Cylinder Head Parts In The Assembly Process With The Exhaust And Intake Valve In The Light Blue Scene Stock Photo Image Of Automotive Casting

Aluminium Gravity Die Casting Alloy Lm25 Deancast Components Ltd Uk Manufacturer West Midlands

Resoltech 60 Alu 25 Aluminium Filled Epoxy Casting System

Aluminum Casting At Rs 250 Kg Aluminium Castings Aluminium Casting Machining एल य म न यम क स ट ग Le Met Corp Bengaluru Id

Company Overview Aluminium Die Casting

Ryobi Aluminium Casting Uk Ltd Linkedin

Aluminium Casting Puri Enterprises Home Facebook

Q Tbn And9gctmpzx84mvbkuq C7vtkgcbzvf8dtqkdviuez Rzxq Usqp Cau

Gravity Die Casting Precision Aluminium Castings

Aluminium Casting Techniques Perla Alucast

Aluminum Castings An Overview Sciencedirect Topics

China De Afgietsels Van De Gieterij Van Het Messing Van Het Aluminium Casting Foundry Company Diy Kopen Aluminium Casting Company Op Nl Made In China Com

Die Casting Wikipedia

Aluminum Gravity Cast Auto Parts Sxlh Aluminum Gravity Casting

Global Aluminum Casting Market Dynamics Analysis Production Supply And Demand Covered In The Latest Research 25 focus

Q Tbn And9gcqwrnjdyfslahk4hbiudfryqpv1i9la Mnvxpnbyl3ae9tedxau Usqp Cau

Gravity Aluminium Castings Packaging Type Wooden Pallet Box Rs 300 Kilogram Id

Aluminium Castings Ballantine Castings Ltd Iron Foundry Bo Ness

China Aluminium Casting Foundry Precision Casting Aluminium Part Factory Suppliers Manufacturers Quotes

Aluminium Casting And Why You Need To Be Careful Diy Molding It Cast Aluminum Molding

Die Casting Aluminium Parts Taiwantrade Com

Oem Aluminium Casting Onderdelen Geanodiseerd Zwart Rood Geel Messing Diepe Stempelen Plated Zink Buy Oem Aluminium Casting Onderdelen Messing Diepe Stempelen Plated Zink Geanodiseerd Aluminim Legering Casting Onderdelen Product On Alibaba Com

Aluminum Gravity Cast Auto Parts Sxlh Aluminum Gravity Casting

Top Ten Aluminium Casting Manufacturers In The World

Magna To Open Aluminium Casting Facility In United Kingdom Aluminium Insider

Sand Casting 2 Pouring Aluminium Youtube

China Aluminum Die Casting Couplings Clutches Aluminium Casting Mould Factory China Die Casting Aluminum

Aluminium Casting Foundry It Cast Foundry Melting Metal

Aluminium Casting Die On Sales Quality Aluminium Casting Die Supplier

Aluminum Casting At Rs 1000 Unit Ahmedabad Id

Aluminum Casting Molds

Aluminium Casting Techniques Sand Casting And Die Casting Processes

Aluminum Die Casting Ningbo Metrics Automotive Components Co Ltd

Stencil Aluminium Casting Process By Julien Carretero

Ceramic Foam Filter Ceramic Filter Foam Filter Aluminium Foundry Casting

Aluminium Casting Grijper Klem Voor Podium Truss Buis 50 Mm Quick Release Klauw Klemmen Aliexpress

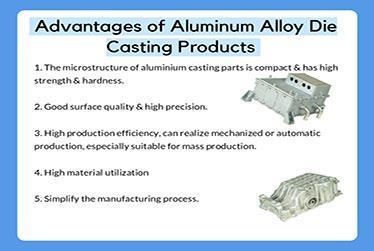

Advantages Of Aluminum Alloy Die Casting Products Emp Tech Co Ltd

Casting Aluminum

Aluminium Drives Corporate Wind Deals To New High Windeurope Recharge

Casting Aluminium With Lost Pla Investment Mold 8 Steps With Pictures Instructables

Aluminium Casting China Aluminium Die Casting Manufacturer

/VAF/Landscape/Vostermans%20Alu%20Foundries%20Gravity%20Aluminium%20Casting%20L.jpg)

Vostermans Alu Foundries

Adc12 Aluminium Casting Gieterij Producten Buy Adc12 Aluminium Casting Gieterij Producten Spuitgieten Onderdelen Aluminium Spuitgieten Product On Alibaba Com

Mws Produkte Sand Casting Aluminium Casting Gravity Die Casting

Aluminium Casting Ssoss Cast Pte Ltd

Alessi Pulcina Aluminium Casting Espresso Coffee Maker 16 5cm Home Bazar

Aluminium Casting Manufacturers Aluminium Casting Companies Aluminum Die Casting And Webcam Parts

Aluminum Workshop How To Determine If An Aluminum Casting Is Weldable

Industrial Background From Part Aluminium Casting Flanges Oil Stock Photo Picture And Royalty Free Image Image

Casting Aluminium Using Lost Foam Method Youtube

Aluminium Casting Grijper Klem Voor Podium Truss Buis 50 Mm Quick Release Klauw Klemmen Aliexpress

Aluminium Casting And Machining For Injection Pump Stock Image Image Of Pouring Part

Aluminium Casting China

Aluminium Casting Method Comparison Pros And Cons Of Different Casting Methods For Aluminium Parts Alteams Aluminium Casting Method Comparison Production Volume Matters

Aluminium Castings Foundry Uneko Spol S R O

Aluminium Castings Foundry Uneko Spol S R O

Aluminium Casting Kontek Machinery

Homemade Budget Aluminum Foundry Youtube

Aluminium Casting Manufacturer About Us Si Castings Si Castings

Die Aluminium Casting And Machining Parts Of Wheels China Casting Part Machining Part Made In China Com

Top 5 Safety Considerations For Metal Casting Harrison Castings

Aluminium Casting Service Super Alloy Casting

Aluminium Casting Parts Aluminum Casting Parts Manufacturer From Pimpri Chinchwad

Q Tbn And9gcrm8czamjm1u1bczbeg1qxbwwomowqpzjnmyqetdotd4pwrkae1 Usqp Cau

Buvo Castings B V

Manufacturer And Exporter Of Aluminium Casting

Aluminium Casting Scrap Application Industrial Price 90 Inr Kilograms Id

What Is Aluminium Casting Quora

Amazing Cast Aluminum Process Using Sand Mold Fast Melting Metal Casting Technology Working Youtube

Production Of Aluminium Castings The Lightness Of The Future

Aluminum Casting Jg Automotive Automotive Components Supplier

Casting Aluminium Imperiaal Spuitgieten Aluminium Aluminium Casting Product Buy Aluminium Casting Product Casting Aluminium Spuitgieten Aluminium Product On Alibaba Com

Aluminium Casting Ingot Manufacturer Supplier India

Pile Aluminium Casting Image Photo Free Trial Bigstock

Zinc Aluminium High Pressure Die Casting Company In China

Which Scrap Aluminium To Use For Casting Flowering Elbow

Log Casting Machine Aluminium Cast House Sistem Technic Industrial Furnaces Kocaeli City Turkey

China Customized Aluminium Casting Riser Cutting Machine Manufacturers Suppliers Factory Wholesale Price Ds Machinery

Aluminium Casting Kontek Machinery

Aluminium Casting And Machining For Injection Pump Stock Photo Image Of Shapes Mechanical

The Aluminium Casting Cylinder Head Parts In The Assembly Process Stock Photo Picture And Royalty Free Image Image

Lm25 Aluminium Casting At Rs 180 Kilogram Aluminum Castings Id

Aluminium Casting