Level Control

Browse Victaulic level control valves product listings for fire protection piping systems Find level control valves for a variety of pipe materials, pressures & sizes.

Level control. Level Indicators Detect and measure the level of a liquid within a tank with level indicators Standard technologies used to measure level include floats, pressure or depth sensors, ultrasonic detection, and conductivity level measurement Learn more about Level Indicators. Full steel level control of the production process Our mould level measurement solutions are designed to run at an exceptionally short cycle time of 5 ms, allowing for perfect control of the casting process – both at automatic startup and in normal operation. Level control (selfemcindustrial) submitted just now by emcindustrial Building new machines for today’s smart factories requires sophisticated control and automation that can only be delivered through multiple solutions and components – including a PLC, HMI, I/Os and motion components such as AC Servo systems and VFDs.

Level Controls Stand Alone These conductivity tank level controls are Lumenite®'s solution for 100's of custom level control operations Industrialeveline™ controls are totally customizable with various options to suite your needs and work with sanitary or industrial probe assemblies. The CheckPoint product is the lowest cost and longest lasting water level controller in the industry for any water level management application We offer simplex and duplex water level controls Call Us For Product Orders US or NonUS. Conductive level switches are sensors that use stainless steel probes with an electrical contact output to measure a specific liquid level Used in conjunction with a level control relay to set and monitor each probe Applications include ponds, reservoirs, sumps, pharmaceuticals, closed vessels and open tanks.

The Level Control System is designed to operate in the event of static changes such as when passengers are entering or exiting the vehicle or quasistatic such as s when the fuel tank is emptying while driving The Level Control System come in various configurations such as hydraulic (hydropneu matic) or pneumatic only systems. Molten Metal Level Control Solutions Precimeter is a premium supplier of molten metal control sensors We specialize in solutions for metal level, transfer and flow control for all metals and alloys Our customers include OEM metal casting machine manufactures, System Integrators and metal casting end users Read more. Water Level Controller 1 Contact Water Level Controller Here a simple circuit to control the Water pumps When the water level in the over 2 Contactless Water Level Controller Apart from the technique discussed above, there can be another way to control 3 A Digital Water Level Indicator.

Level Control Valve with Modulating Horizontal Float FP LEARN MORE Level Control Valve with BiLevel Electric Float FP LEARN MORE GLOBAL PROJECTS 50 YEARS 50 YEARS OF FIELD EXPERIENCE, MADE US EXPERTS!. Level Control Products Our level control products are perfect for use with large and medium industrial tanks and storage vessels We offer level sensors, float switches, optical switches, and ultrasonic transmitters and controllers to meet your range of level sensing and control applications Liquid level control switches are the components of liquid control systems that control the power to the pu MORE. One push of the button starts a complete validation cycle to ensure all systems are working properly PROUDLY MADE IN THE USA All of our liquid level controls and liquid level sensors are assembled right here in the USA where we monitor every step of the process.

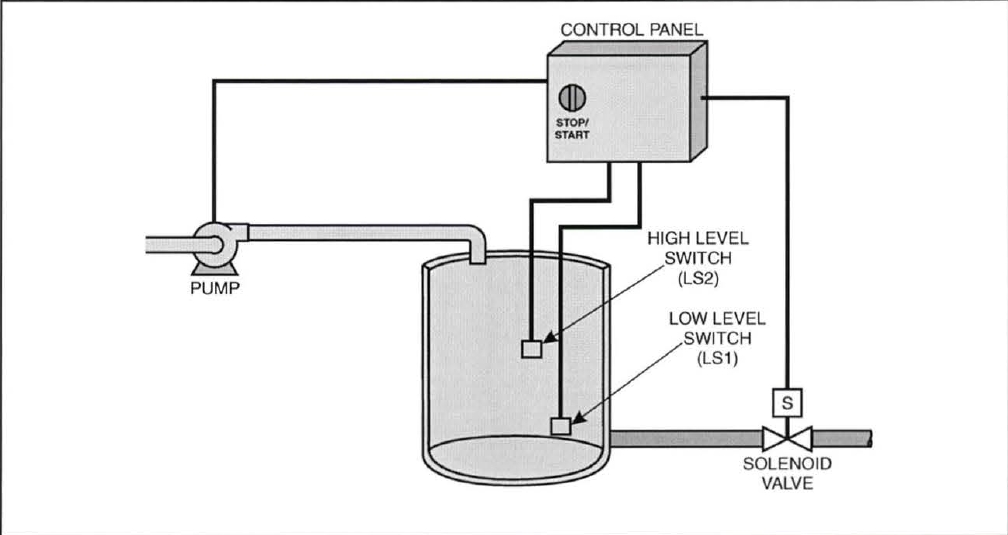

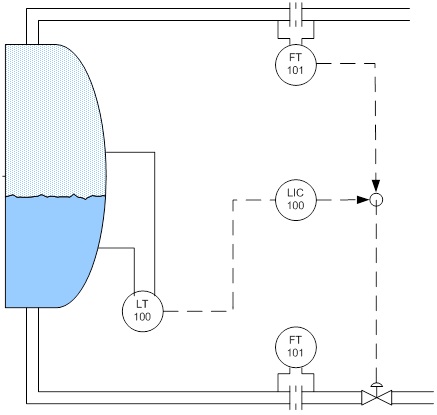

Madison’s R21 controller is ideal for tank level control between two points For larger applications, Madison also offers Tilt level float switches like the M41, which are ideal for sumps, tanks or ponds to directly control small pumps for liquid level control between 6” to 36” For singlephase devices, such as solenoids and pumps with fractional horsepower motors, a customized double pole relay circuit may also be used for either filling “PumpUp” or draining “PumpDown. Master Level Controls Co has been providing integrated level controls for Municipal Water Systems since 1948 Each application is engineered for the highest degree of functionality, and superior quality for jobs requiring the most cost effective controls Our standard control products can be equipped with many optional features. The best method is to feed forward (FF) the steam flow to the level PID loop and cascade the output of that loop to the setpoint of a boiler feedwater (BFW) flow loop This arrangement is called “Three Element Drum Level Control” (3E) because the algorithm uses level, BFW flow, and steam flow.

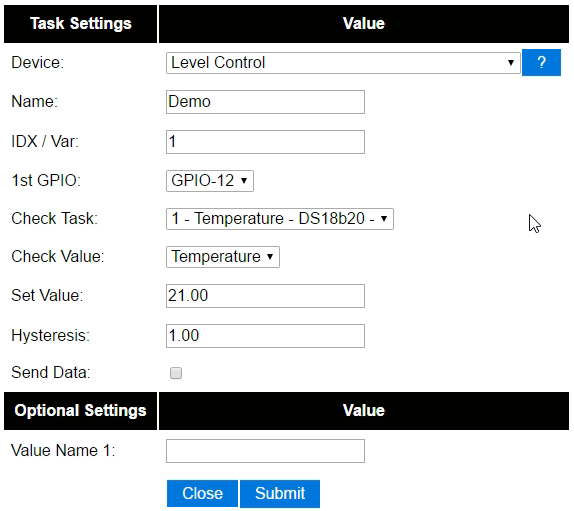

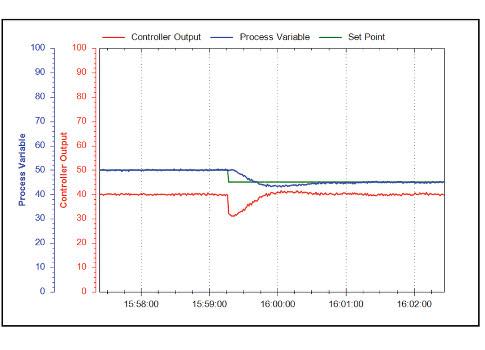

The Level Control System is designed to operate in the event of static changes such as when passengers are entering or exiting the vehicle or quasistatic such as s when the fuel tank is emptying while driving The Level Control System come in various configurations such as hydraulic (hydropneu matic) or pneumatic only systems. That is, it should start controlling when level increases above 213mm, and fully open when level reaches 302 mm Between 142 mm and 213 mm both valves should be closed. Go GLOBAL PRESENCE Locate your local office Go.

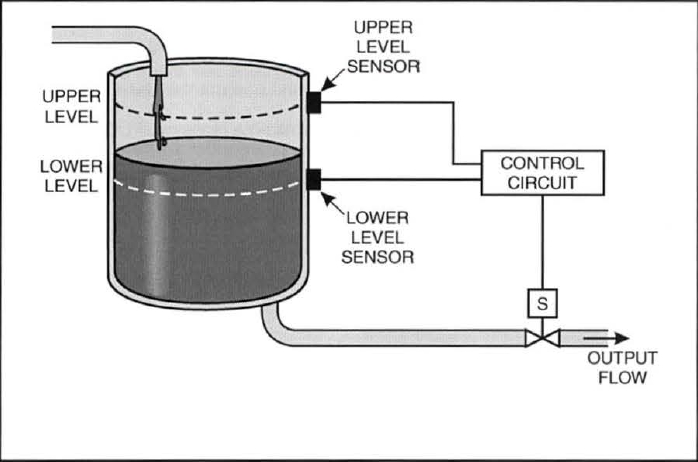

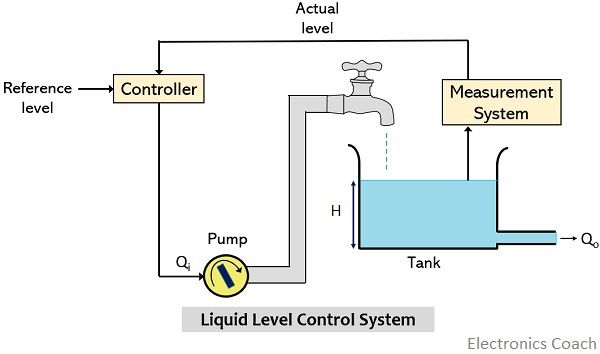

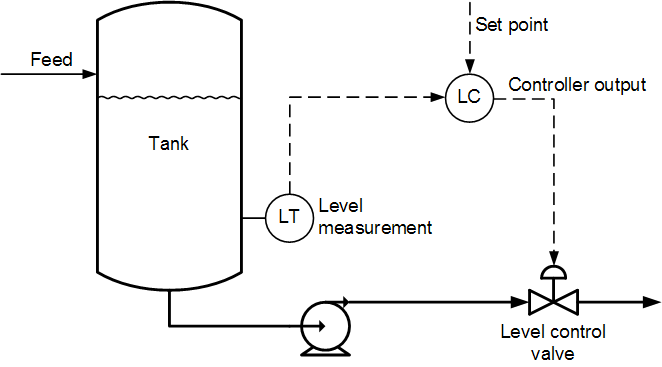

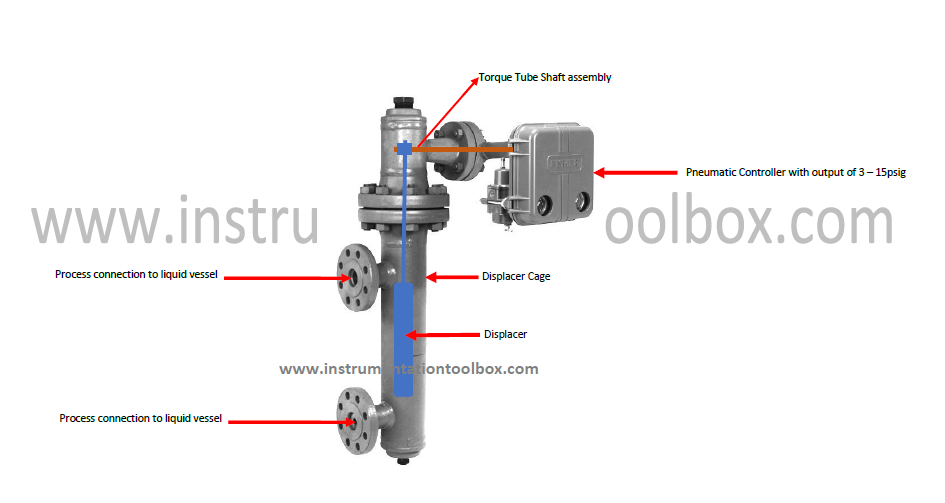

In level control and detection applications, the liquid level of a tank or vessel will vary at a continuous pace over a period of time In order to know when failure occurs or when the level goes dangerously high or low, it is critical to have a level control monitoring solution in place to prevent expensive damage, flooding or run dry situations A single point optical liquid level switch installed at the points in the tank or vessel deemed to be critical will prevent over spilling or. The position of the surplus valve should be 0% to 100% for a corresponding level range of 213 mm to 302 mm;. The first instrument in this control system is the level transmitter, or “LT” The purpose of this device is to sense the water level in the steam drum and report (“transmit”) that measurement to the controller in the form of a signal.

The first schematic shows how to adapt the water level control to bigger pumps still rated at 1Vac You would have to get a Power Relay part number ADPR401C1A from Automation Direct dot com This is a SPDT (Single Pole Double Throw) relay, which means it has only two sets of contacts and three terminals for one line only. MLST or MLXT 42 Level Transmitters provide a constant level measurement of liquid in a tank This control technology is for petroleum, food & dairy, petrochemical, pharmaceutical, sewage & waste products or any other industry measuring conductive or nonconductive liquids Our transmitters also work with moist, granular solids. Level control (selfemcindustrial) submitted just now by emcindustrial Building new machines for today’s smart factories requires sophisticated control and automation that can only be delivered through multiple solutions and components – including a PLC, HMI, I/Os and motion components such as AC Servo systems and VFDs.

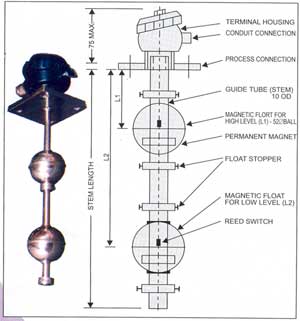

Float level switches are sensors with an electrical contact output at a specific liquid level Applications include level control, valve control, deaerators, condensate tanks, oil level control, drip legs, and boilers A few models are designed for the automation of pumps, specifically filling and draining of tanks, wells, and reservoirs. Level Controllers The Nina liquid level controller can be connected to any sensing method including Float Switches, Pressure Switches, and Physical probes of all different types of material Nina an be set to control 1 to 6 switch points in a single head, making the old “Float tree” Obsolete. Comparison of Level Control Configuration for Industry Level control is a very common process requirement for vessels across a wide range of industrial and research applications The most common level control configuration is an on/off valve triggered by a level sensor In some industrial systems a flow control valve is configured for level control where the input to the flow control valve is provided by an analog level sensor.

And can't fail like pressure transducers. The Model DLC can be used as a high level switch, a low level switch, or a plugged chute detector Additionally, the model DLC may also operate as a material presence control on a conveyor belt, and a high level indicator in a crusher box The Model DLC is commonly used when intrusion into the bin is not acceptable, not possible or not allowed. The universal electronic water level controller from WATERLINE CONTROLS® provides precise control that compensates for wave action and manages water levels to within 1/8" of operating range Drycontact digital circuitry easily integrates with existing building automation systems, with a separate relay for each set point.

Go GLOBAL PRESENCE Locate your local office Go. Liquid level controllers are electrical devices that can detect when vessel levels are too low or too high When a probe senses a specific liquid level, it will automatically refill the system They use the conductivity of the liquid to complete a circuit, using probes to detect the liquid levels and replenish them when necessary. To reduce introduction and spread of new variants of SARSCoV2, CDC issued an Order pdf icon PDF – 9 pages effective January 26, 21 It requires all air passengers arriving to the US from a foreign country to get tested for COVID19 infection no more than 3 days before their flight departs and to provide proof of the negative result or documentation of having recovered from COVID19 to.

Liquid level float switches are used to measure the level of a liquid inside a container These floats can simply indicate the level of the liquid, or they can hold other functions like turning pumps on or off How they are made and installed dictate what they will do and how they will work for you!. Level control Magnetrol offers an extensive range of innovative level controls for process industries Click on the product category below or use the filters at the left to find the Magnetrol products that will meet your level or interface control challenge. WATERMAN AUTOMATIC DOWNSTREAM LEVEL CONTROL GATES provide constant downstream level control regardless of upstream level conditions or downstream demands With over 30 years experience and the largest worldwide installed base, Waterman stands apart as the leading provider of automatic level control gates Using a proven, proprietary design, Waterman’s level control gates automatically maintain a specified water level and operate without any outside power or motor, free of any manual.

Today, level measurement technology is the basis for management and process control in the chemical, petrochemical, environmental and other related industries Our comprehensive program enables us to help you solve your particular measurement and control problems and to detect the precise level of any medium, under a wide range of conditions. These universal electronic water level controls provide precise wave action compensation and water level control Modular, quick connect design uses no mechanical floats Choose from controls with high and low level alarms, high level alarms, fill height only alarms and combination styles Water level controls from Grainger resist moisture, dust and corrosion. The first instrument in this control system is the level transmitter, or “LT” The purpose of this device is to sense the water level in the steam drum and report (“transmit”) that measurement to the controller in the form of a signal In this case, the type of signal is electronic type DP Level Transmitter.

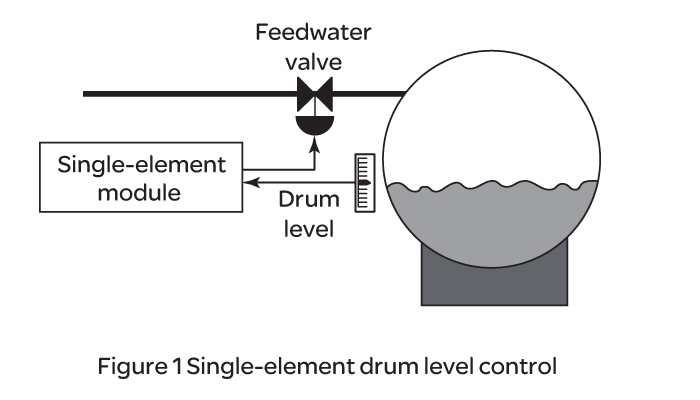

Drum Level Control Strategies Two element Drum level Control This drum level control design is particularly suitable in case of single drum boilers Three element Drum level Control In this design, three elements are used, each for controlling level, steam and Enhanced three element drum. Entitylevel controls are internal controls that help to ensure that management directives pertaining to the entire entity are carried out They are the second level of a topdown approach to understanding the risks of an organization Generally, entity refers to the entire company. A CASECONTROL STUDY TO DETERMINE RISK FACTORS FOR ELEVATED BLOOD LEAD LEVELS IN CHILDREN, IDAHO MILDRED MAISONET, FRANK J BOVE,AND WENDY E KAYE ~genc'y for i'oxic Substances and Disease Registry Division of Health Studies Epidemiology and Surveillance Branch children with elevared blood lead levels living in the vicinity of a defunct mining and.

Level indicators utilize a mechanical device, such as a float, or a sensor with output signal to indicate the level within a tank Level controllers are, essentially, indicators with integrated control output which allows for functions such as on/off, alarms, etc Level Indicator Technology Float Float level instruments are mechanical devices that move in conjunction with the level of the liquid medium. The original information for decisionmaking and developing control signals is transmitted from lower to higher levels, and the. PID controller is a controller into designing an intelligent automatic level powerful and complex controller It eliminates offset error control This system gives accurate level control and as Proportional control provides better control due to its output stead with smooth transition process This system can use in operate linearly early.

Here a simple circuit to control the Water pumps When the water level in the over head tank exceeds the required level, the pump automatically turns off and stops the pumping process thus preventing the over flow of water It uses a relay to cut off the power supply to the water pump The circuit is build using the following components. Level control (selfemcindustrial) submitted just now by emcindustrial Building new machines for today’s smart factories requires sophisticated control and automation that can only be delivered through multiple solutions and components – including a PLC, HMI, I/Os and motion components such as AC Servo systems and VFDs. Browse Victaulic level control valves product listings for fire protection piping systems Find level control valves for a variety of pipe materials, pressures & sizes.

The ideal lift station level control system will always start the pumps no matter how much grease is in the wetwell That's why you need the FOGRod It works so well because it is simple almost as simple as floats, but with much less maintenance;. Level control valves maintain a constant level in a liquid supply such as a reservoir Level control valves do this by regulating the flow into the liquid supply which maintains a constant level to meet the usage demands See Bermad’s range below WWX – Altitude Control Valve AS5081, WaterMark. Float type level switches are used many different applications to indicate high or low level conditions, control pumps or valves, and provide indication These simple devices are critical to hundreds of different applications When the liquid level reaches the float, the float raises up and trips the internal reed switch to make a connection.

Level control (selfemcindustrial) submitted just now by emcindustrial Building new machines for today’s smart factories requires sophisticated control and automation that can only be delivered through multiple solutions and components – including a PLC, HMI, I/Os and motion components such as AC Servo systems and VFDs. Level control is a very common process requirement for vessels across a wide range of industrial and research applications The most common level control configuration is an on/off valve triggered by a level sensor. In level control and detection applications, the liquid level of a tank or vessel will vary at a continuous pace over a period of time In order to know when failure occurs or when the level goes dangerously high or low, it is critical to have a level control monitoring solution in place to prevent expensive damage, flooding or run dry situations.

Drum Level Control Systems are used extensively throughout the process industries and the Utilities to control the level of boiling water contained in boiler drums on process plant and help provide a constant supply of steam If the level is too high, flooding of steam purification equipment can occur. Two element drum level control The twoelement drum level controller can best be applied to a single drum boiler where the feedwater is at a constant pressureThe two elements are made up of the following Level Element a proportional signal or process variable (PV) coming from the drum level transmitter This signal is compared to a setpoint and the resultant is a deviation value. Twoelement control is made up of Level Element and Steam Flow Element Level Element The drum level transmitter as a process variable (PV) This signal is compared to a setpoint, and the resultant is a deviation value The controller acted upon this signal, which generates corrective action in the form of a proportional value.

UWT Level Control India Pvt Ltd RK Plaza, Survey No 6/3 Plot No 17 Viman Nagar Pune, India Phone 91 2 674 1000 Fax 91 2 674 1001 Contact Vikas Kirange Area Manager vikaskirangeuwtindiacom Mobile 91 East Regional Office UWT Level Control India Pvt Ltd Flat – 3B, 9 Majhipara Road James Long Sarani. Level Control Valve with Modulating Horizontal Float FP LEARN MORE Level Control Valve with BiLevel Electric Float FP LEARN MORE GLOBAL PROJECTS 50 YEARS 50 YEARS OF FIELD EXPERIENCE, MADE US EXPERTS!. The universal electronic water level controller from WATERLINE CONTROLS® provides precise control that compensates for wave action and manages water levels to within 1/8" of operating range Drycontact digital circuitry easily integrates with existing building automation systems, with a separate relay for each set point.

Liquid Level Controllers The liquid level control unit is an electrical device with contacts that open and close in response to liquid levels The fitting is a housing that holds the probes (or floats), insulates them from the vessel, and provides a means of The probe is a sensor that extends. Level Controllers 01NB/01E Pneumatic & Electric Liquid Level Control, High Pressure NoBleed 7400 Snaptrol Pneumatic & Electric Liquid Level Control, Low Pressure NoBleed 1800 Pneumatic & Electric Liquid Level Control, Low Pressure NoBleed 6900 Cantilever Liquid Level Control. Level Controllers The Nina liquid level controller can be connected to any sensing method including Float Switches, Pressure Switches, and Physical probes of all different types of material Nina an be set to control 1 to 6 switch points in a single head, making the old “Float tree” Obsolete.

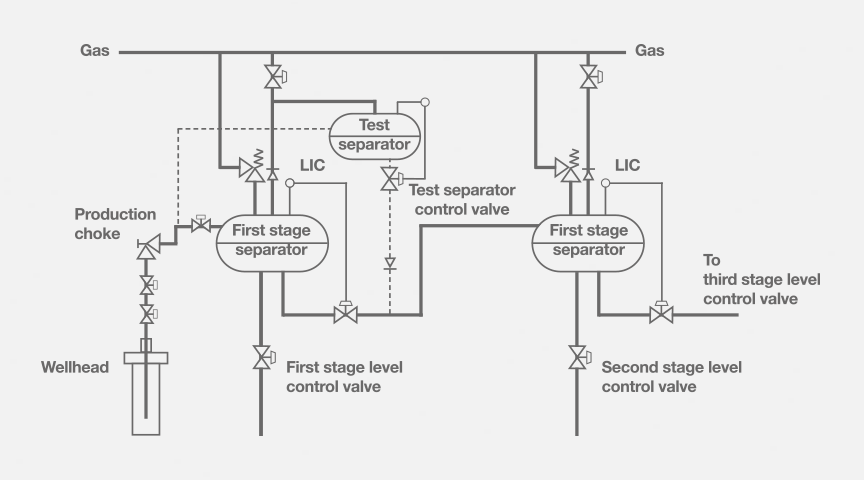

General information about the control loop (s) The issue is related to a deaerator (DA) level control There are currently two loops controlling the DA level, ie the makeup control loop and valve and the surplus control loop and valve The setpoints of the loops are set at 142 mm and 213 mm, respectively. Modulating level control Description A modulating level control system consists of a capacitance probe and appropriate controller, which provides a modulating output signal, typically 4 mA Refer to Figure 5 This output signal may be used to affect a variety of devices including Modulating a control valve Operating a variable speed pump drive. Way simpler than ultrasonics;.

Control Level any one of the relative gradations of sets of control elements in an integrated system, grouped and separated according to the hierarchical principle of control The control elements of various levels are interconnected and strictly subordinated In hierarchical control systems, each subdivision, or subsystem, solves only problems of its own level;. Worldclass system, support and performance The Siemens Electronic Water Level Control System maintains a consistent water level, which is crucial for efficient, reliable boiler operation The Siemens Modulating Water Level Control System offers the following advantages For boilers with rapidly fluctuating steam loads, the Siemens system has the capability to include dualelement control, minimizing boiler drum swell and shrink effects. Level control encompasses a wide variety of technologies that sense and provide control feedback on fluid levels in tanks, vats, silos, reservoirs etc.

To reduce introduction and spread of new variants of SARSCoV2, CDC issued an Order pdf icon PDF – 9 pages effective January 26, 21 It requires all air passengers arriving to the US from a foreign country to get tested for COVID19 infection no more than 3 days before their flight departs and to provide proof of the negative result or documentation of having recovered from COVID19 to.

W 30 Y Eliptix Level Control Valve Vertical Float

Predictive System Level Control

Cp7 Dual Fill Electronic Water Level Control

Level Control のギャラリー

Level Control Systems How They Work

Surge Tank Control Modeling And Control

Nylon 1 2 Inch Automatic Water Level Control Valve Rs 399 Piece Id

Hoogheffende Palletwagen Met Level Control Logitrans

Separator Level Control Systems Kent Introl

Q Tbn And9gcteri1xq Oqyynqii5vejizuyvjs6wszgvlay Ksf64oacy0dlq Usqp Cau

Water Level Control Relay Ssr 04 Din Rail Mounting Liquid Level Relay Water Level Controller Control Relay Controller Controlcontrol Level Aliexpress

Kryobehalter Niveauregelgerat Eng Kgw

Tank Level Control And Monitoring In Food Manufacturing Processes Yokogawa Electric Corporation

Wireless Water Level Controller At Rs 10 Piece Wireless Water Level Indicator व यरल स व टर ल वल क ट र लर Tirth Controls Rajkot Id

Liquid Level Controller Yamada Europe

Human Level Control Through Deep Reinforcement Learning Presentation

Products Truma Levelcontrol Set

Control A Water Tank Level Dynamics And Control

Boiler Water Level Control For Modern High Pressure Watertube Boiler

Pin On Fred

Water Level Control In A Tank Matlab Simulink Mathworks Espana

Relay Based On Off Controller Level Control

Tank Level Tuning Complications Control Notes

Kybsim

When The Level Matters Gf Piping Systems Ltd

Solved A Liquid Level Control System Can Be Configured In Chegg Com

Protective 2v Din Rail Water Level Control Switchce 3 Phase Industrial Water Flow Switch Liquid Level Control Relay Supplier Buy Industrial Water Flow Switch Liquid Level Control Relay Supplier Protective 2v Din

Rockford Plc Punch Level Control Venderparts Nl Venderparts Nl

Grl8 01 02 Level Control Relay Manufacturer For 10 Years

Water Level Controller

Three Element Drum Control System In Boiler Water Level Control Marinesite

Tsc Level Control Gap

Predictive System Level Control

Float Switch Automatic Liquid Water Level Controller Contactor Sensor 2v 16a For Sale Online Ebay

What Is Liquid Level Control System Working And Transfer Function Of Liquid Level System Electronics Coach

Steam Boiler Water Level Control The Industrial Steam Valve And Process Control Blog

How A Pneumatic Displacer Level Sensor Is Used To Control Liquid Level Learning Instrumentation And Control Engineering

Piping System Controls Pumps Systems

Tuning Surge Tank Level Control Loops Dataforth

Eliminating Hidden Maintenance Costs With Condensate Recovery Process Level Control Magnetrol

Kiss Xh M3 Full Automatic Water Level Controller Pump Switch Module Ac Dc 12v Relay Shopee Malaysia

Levelcontrol Let S Control It

Liquid Level Control Relay Description And Installation Youtube

Problem On Pressure And Level Control Loops Instrumentationtools

Flowline Liquid Level Control Selection Guide From Cole Parmer Germany

Level Switches Operating Principles Technical Guide India Omron Ia

Solar Water Tank Water Tower Pool Automatic Water Level Control Valve Controller Plastic Float Valve Inlet Valve Switch Valve Switch Valve Controllevel Control Valve Aliexpress

Level Switches Discrete Process Measurement Automation Textbook

Comparison Of Level Control Configuration For Industry

An Overview Of Automatic Level Control

China Fisher Pneumatic Level Controller Manufacturers Suppliers And Company Discount Products Shaanxi Wantong Automation Equipment Co Ltd

Level Control Level Control Relay Manufacturer For 10 Years Geya

Boiler Water Level Control System Example Introduction To Industrial Instrumentation Automation Textbook

Level Control Selection Guidelines Process Industry Forum

Practical Process Control System Questions Answers 10 Instrumentation Tools

Relay Based On Off Controller Level Control

Using Liquid Level Control Relays Macromatic

Level Control Experiment

Uwt Gmbh Level Control Linkedin

Process Control Fundamentals Technology Transfer Services

Iv Water Level Control System Computer Aided Control Systems

Comparison Of Level Control Configuration For Industry

Liquid Fluid Water Float Tank Level Switch Circuit Diagram Using Relay

Kido Liquid Level Control Switch Water Level Controller Float Switch View Water Level Control Switch Kido Product Details From Fortuntek Industrial Co Ltd On Alibaba Com

A Water Level Control System Download Scientific Diagram

Products

China Electrical Water Level Control Float Switch Level Sensor For Hot Water Tank China Electrical Water Level Control Float Switch Float Type Fuel Level Sensor

Level Control System An Overview Sciencedirect Topics

Level Control Systems How They Work

Boiler Drum Level Control Yokogawa Electric Corporation

Tank Level Control Madison Company

Water Pump Cable Float Level Control Switch Buy Pump Switch Water Level Float Switch Water Pump Float Switch Product On Alibaba Com

Cp8 Dual Fill With Low Alarm Electronic Level Control Water Level Controls

Synoptic Schematics Of A Toxic Liquid Level Control System Download Scientific Diagram

How A Pneumatic Displacer Level Sensor Is Used To Control Liquid Level Learning Instrumentation And Control Engineering

Boiler Drum Level Control Eurotherm By Schneider Electric

Control Engineering Optimizing Strategy For Boiler Drum Level Control

Tuning Level Control Loops Dataforth

Comparison Of Level Control Configuration For Industry

Magnetic Level Switch Top Mounted Magnetic Level Switch Industrial Control Instruments Flow Switches Flow Indicators Mumbai India

An Overview Of Automatic Level Control

Iv Water Level Control System Computer Aided Control Systems

Gic Make Liquid Level Controller 400v Cat No 4431ad1 Amazon In Industrial Scientific

Water Level Control In A Tank Matlab Simulink Mathworks Espana

Ayvaz Level Control Level Controllers Level Electrode Level Gauge Magnetic Mechanic Level Switch Float Switch

Overview Of Level Switches Omron Industrial Automation

China Float Electronic Level Switch Water Fuel Level Sensor Automatic Water Level Controller China Level Controller Fuel Level Controller

Cp16 Pump Down With High Alarm Water Level Controls

A Schematic Diagram Of The Liquid Level Control System Download Scientific Diagram

Feedforward Or Cascade Control Dynamics And Control

Level Control System On Off Control Modulated Control

Liquid Level Control Sensor Hb Series Parker Na

Q Tbn And9gcqtkrdlhtlnzzegpm6je5cobhfe6skpzu7kmwjrxavifyq3e9tp Usqp Cau

Level Control Adaptive Level Control Control Global

Solved The Following Figure Illustrates A Liquid Level Co Chegg Com

Automatic Water Level Controller Detailed Circuit Diagram Available

Q Tbn And9gcs80adkehdlpqgqg Ffn Jaiqwtcsx0qsxx Dqe1ki8yx2f4 Usqp Cau

Steam Drum Level Controlling System Single Element Double Element Three Element Askpowerplant

How Level Control Valves Work Enggcyclopedia

Integrating Processes Liquid Level Control Instrumentation Tools

Control Engineering Tuning Pid Loops For Level Control

Liquid Level Control Using Flow Loop Instrumentationtools

Block Diagram Of Liquid Level Control System In A Buffer Tank Download Scientific Diagram

Q Tbn And9gcr 7f8s4smsepmylwfzjo0oyrprea7f1zpxt1uosvlpiwdrug Usqp Cau

Level Versus Flow Control Control Notes